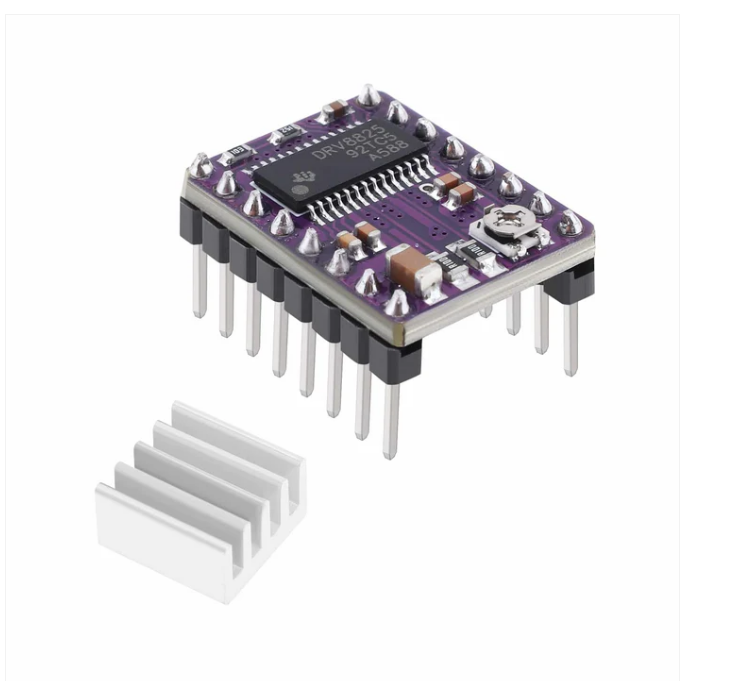

DRV8825 Stepper Motor Driver Module 4-Layer with

Price 110.0 INR/ Piece

DRV8825 Stepper Motor Driver Module 4-Layer with Specification

- Refilable

- Yes No

- Body Material

- Metal

- Material

- Plastic

- Size

- Standard

- Use

- Printing

- Color

- Purple

DRV8825 Stepper Motor Driver Module 4-Layer with Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Delivery Point (DP), Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Paypal

- Supply Ability

- 3 Pieces Per Day

- Delivery Time

- 3 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About DRV8825 Stepper Motor Driver Module 4-Layer with

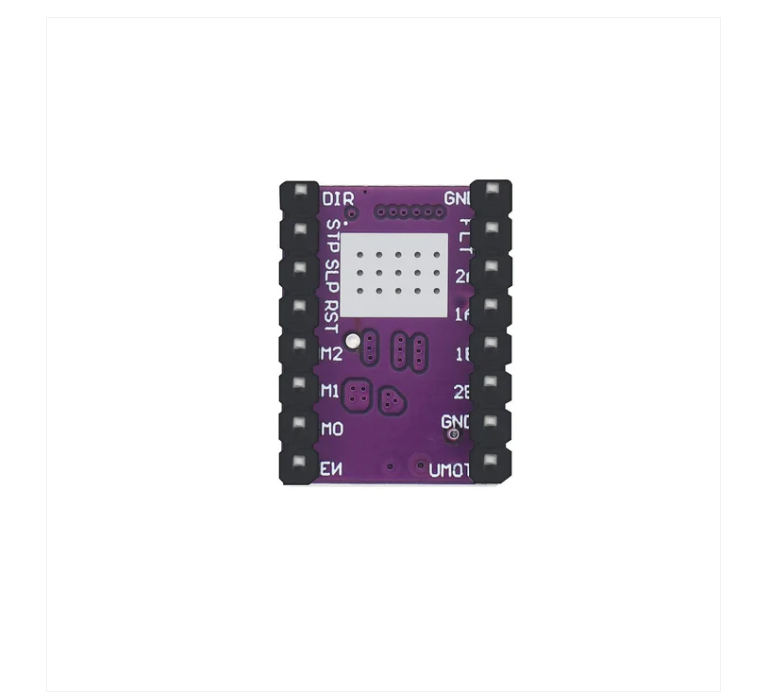

The DRV8825 Stepper Motor Driver Module is an excellent motor driver solution for printers, scanners, and automated equipment applications, and is often used by our customers for the 3D Printers we sell. The DRV8825 Stepper Motor Driver block consists of N-channel power MOSFETs set to full H-bridge to drive motors at 24V with up to 2.5A on each of the channels via two H-bridge drivers and a microstepping indexer originally intended for bipolar Stepper Motors.

This DRV8825 Stepper Motor Driver offers an easy STEP-DIR interface for simple controller circuit interfacing, as well as physical mode pins to configure the motor microstepping modes between full-step and 1/32-step. The DRV8825 Stepper Motor Driver unit also features multiple decay modes, configurable to slow decay, fast decay or mixed decay mode.

Additionally, this DRV8825 Stepper Motor Driver offer protection features to safeguard from overcurrent, short circuits, Undervoltage, as well as high temperatures. To add some extra functionality and make your life easier, it has an nFAULT pin that indicates if there is a fault, so you can quickly identify a problem and fix it before it becomes costly.

DRV8825 Stepper Motor Driver is the upgrade of A4988, 4-layer PCB for improved heat dissipation and decreased chip resistanceSimple step and direction control interface stepper Motor Driver (Header Pins Soldered) is a breakout board for DRV8825 micro-stepping bipolar stepper motor driver. Could be operated from 8.2V to 45V and can deliver up to approximately 1.5A per phase.

Enhanced Performance for Printing and CNC

The DRV8825 Stepper Motor Driver Module offers precise current control and low noise operation, making it ideal for 3D printers and CNC machines. Its 4-layer design aids thermal management and overall reliability, even under continuous operation. The device suits applications requiring high fidelity motor control, enhancing both productivity and print quality.

Reliable Construction and Easy Integration

Manufactured using a combination of metal for the body and plastic for other components, the module delivers strength without unnecessary weight. Its standard size ensures compatibility with a wide range of devices, making assembly and replacement straightforward, whether you're upgrading or working on a new project.

FAQ's of DRV8825 Stepper Motor Driver Module 4-Layer with:

Q: How do I install the DRV8825 Stepper Motor Driver Module in my printer?

A: To install the DRV8825 module, carefully insert it into the stepper driver slot on your control board, ensuring correct pin alignment. Secure any heatsink if needed and connect the stepper motor and power supply as indicated. Double-check wiring before powering on your device.Q: What are the benefits of using a 4-layer DRV8825 module?

A: The 4-layer PCB design greatly improves heat dissipation, reduces electrical noise, and enhances performance stability, ensuring reliable operation over long periods and under heavy demand.Q: Where can I source the DRV8825 Stepper Motor Driver Module in India?

A: This module is available across India through various channels, including distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers. Many reputable electronics outlets and online platforms stock this item.Q: When should I consider replacing my stepper motor driver?

A: You should replace your stepper motor driver if you notice irregular motor movement, excessive heat, or decreased performance despite correct wiring. Regular checks are recommended for frequently used machines.Q: What is the recommended process to optimize the performance of the DRV8825 module?

A: Properly set the current limit using the adjustment potentiometer, ensure adequate cooling through a heatsink or fan, and install the module on a compatible, stable PCB to maximize its lifespan and efficiency.Q: Can this module be used with both refilable and non-refilable printing systems?

A: Yes, the DRV8825 driver module is suitable for both refilable and non-refilable 3D printing systems, as its primary role is precise stepper motor control regardless of the filament delivery mechanism.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 3D pen-printer-Accessories Category

0.4mm 3D Printer Nozzle 0.4mm MK8 M6 Nozzle 3D

Price 25.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Material : Metal

Color : Golden

Use : Printing

GT2 Timing Belt 1M GT2 Width 6mm Black Open Timing Belt

Price 399.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Material : Synthetic Rubber

Color : Black

Use : Printing

Creality Ender 3d Pen Printer V2 FDM - 220x220x250mm

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 220*220*250mm

Material : Polylactic Acid (PLA)

Color : Black

Use : common

Micro Endstop Switch Micro Switch Mechanical End Stop

Price 15.0 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Material : Plastic

Color : Black

Use : Printing

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese