Call: +918448223338 08045478320

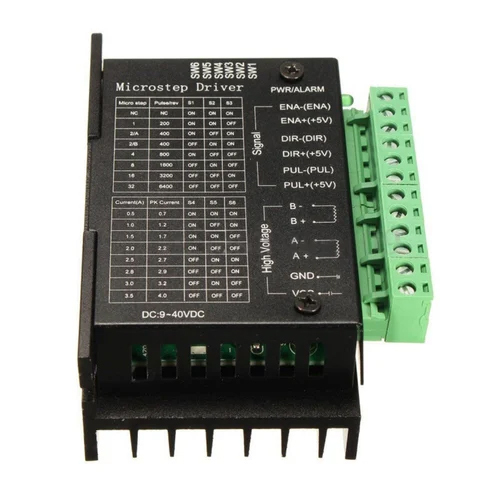

DM542 Stepper Motor Driver Digital Stepper Driver Controller CNC Machine For 3D Printer Accessoriesrs

Price 779.0 INR/ Piece

MOQ : 1 Piece

DM542 Stepper Motor Driver Digital Stepper Driver Controller CNC Machine For 3D Printer Accessoriesrs Specification

- Voltage

- 24 Volt (v)

- Product Type

- Other

- Output Power

- 4.5 Ampere (amp)

- Frequency (MHz)

- 20 Kilohertz ( KHZ )

- Protect Feature

- Other

- Phase

- Single Phase

- Power

- 60 Volt (v)

- Color

- Black

- Weight

- 250 Grams (g)

- Warranty

- 1 Year

- Material

- metal

- Features

- Over Voltage Protection Short Circuit Protection Reverse Polarity Protection Auto Cut-off When Fully Charged Digital Display Fan Cooling

DM542 Stepper Motor Driver Digital Stepper Driver Controller CNC Machine For 3D Printer Accessoriesrs Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Delivery Point (DP)

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 3 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About DM542 Stepper Motor Driver Digital Stepper Driver Controller CNC Machine For 3D Printer Accessoriesrs

A Stepper Motor Driver that anticipates your needs. The DM542T isn't just a driver; it's an intelligent digital control system, meticulously crafted with a cutting-edge DSP algorithm. Experience a new echelon of smoothness, where vibrations are minimized and torque is consistently powerful across the entire speed range, banishing frustrating mid-range instability. Setting up your NEMA 17 or 23 motor becomes effortless thanks to its ingenious auto-identification and parameter auto-configuration, swiftly dialling in the perfect settings. Unlike conventional analogue drives, the DM542T empowers your stepper motor to operate with remarkably reduced noise and heat, delivering noticeably smoother motion. For applications demanding peak performance and unwavering reliability, the DM542T stands out as the ideal solution.Engineered for Precision Motion Applications

The DM542 Stepper Motor Driver delivers accurate and smooth control for stepper motors, making it an excellent choice for CNC machinery and 3D printing. Its advanced digital features and high current output ensure your motion systems are responsive and precise with every command.

Safety and Reliability at The Forefront

This digital stepper driver provides comprehensive protection, including over-voltage, short circuit, and anti-reverse measures. The auto cut-off feature ensures safety during prolonged use, while the integrated fan cooling system maintains optimal temperature for stable operation.

Versatile Integration in Industrial Settings

Whether for automation, prototyping, or manufacturing, the DM542 driver's compact design and robust metal construction allow easy integration into various machines. Its compatibility with numerous stepper motors, and digital display for status monitoring, add convenience and versatility to your setup.

FAQ's of DM542 Stepper Motor Driver Digital Stepper Driver Controller CNC Machine For 3D Printer Accessoriesrs:

Q: How do I install the DM542 stepper motor driver in my CNC machine or 3D printer?

A: Installation involves connecting the DM542 to your system's stepper motor wiring, power supply (24V or up to 60V), and control signals. Ensure connections correspond to your machine's requirements. Refer to the included manual for wiring diagrams and configuration details.Q: What protection features does the DM542 driver offer during operation?

A: The DM542 integrates comprehensive protections such as over-voltage, short circuit, and reverse polarity protection. It will automatically cut off power when fully charged and is equipped with fan cooling to prevent overheating, ensuring your equipment remains safe during continuous operation.Q: When should I use the DM542 stepper driver in my automation projects?

A: Use the DM542 when your application demands precise motor control, particularly with CNC machinery or 3D printers requiring up to 4.5A output and reliability under continuous use. Its digital control capabilities are ideal for high-frequency operation (20 kHz) and exact positioning tasks.Q: Where is the DM542 driver manufactured and available for purchase?

A: The DM542 driver is produced and distributed in India. It is available via multiple channels-including distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers-making it accessible for both domestic and international buyers.Q: What benefits can I expect from using this stepper motor driver?

A: By employing the DM542, users gain smooth and accurate motor performance, enhanced equipment safety, and durable hardware. The digital display aids in easy status monitoring, while protective features ensure longevity and reduced risk of operational faults.Q: How does the digital display enhance the usage experience?

A: The digital display provides real-time feedback on driver status and operational parameters, enabling quick diagnostics and adjustment without the need for additional equipment. This feature streamlines troubleshooting and system monitoring during routine use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stepper Motor Drives Category

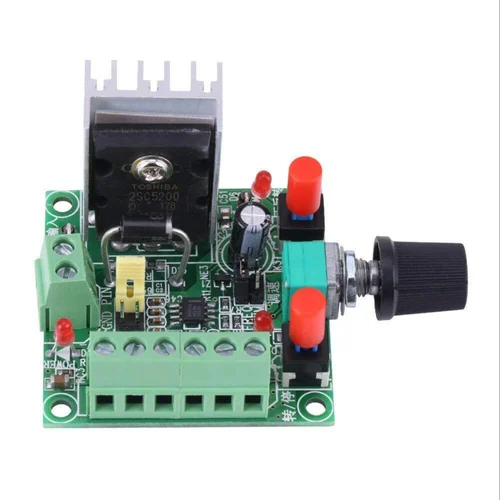

Stepper Motor Driver Speed Board Controller Pulse Signal Generator Module - RS1862

Price 840 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Green

Voltage : 15160 Volt (v)

Product Type : Other, Stepper Motor Driver Speed Board Controller Pulse Signal Generator Module

Sealed Type : Mechanical Seal

TB6600 4A 9-42V Stepper Motor Driver CNC Controller

Price 399 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Voltage : 942 Volt (v)

Product Type : Other, Stepper Motor Driver CNC Controller

Sealed Type : Mechanical Seal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese